手 机:(86)13425186889

电 话:(86)0755-25321990

传 真:(86)0755-25321964

邮 箱:HRJ-666888@163.com

邮 编:518031

联系人:王小姐

网 址:www.sz-hrj.com

地 址:深圳市龙华区龙华街道品创源科技园A-B栋2楼

| ALUMINUM ELECTROLYTIC CAPACITORS SPECIFICATION FOR APPOVAL

铝 电 解 电 容 器 规 格 承 认 书 表1:承认项目 Type Dimensions | |||

|

Customer 客 户 |

|

Vendor 供应商 |

|

|

Used Spec 通用规格 |

100UF16V |

Product Name 品 名 |

Aluminum Electrolytic Capacitor 铝电解电容器 |

|

SizeφD×L(mm) 外型尺寸 |

5*7 |

Operating Temperature Rage 使用温度 |

-40~+105℃ |

|

Rated Voltages Range(V) 额定电压 |

16V |

Capacitance Tolerance(20℃,120Hz) 容量范围±20% |

上限120uF |

|

下限:80uF | |||

|

|

ΦD±β(电容直径) |

5mm±0.5 | |

|

L±a(电容高度) |

7mm±1.0 | ||

|

P±0.5(脚距) |

2.0mm±0.5 | ||

|

Φd±0.05 |

0.6mm±0.05 | ||

表2:额定值与特性 TABLE1 RATING&CHARACTERISTIC.

|

1 |

泄漏电流 I |

I≤0.01CV或3uA取较大值 施加额定电压1分钟I=0.01CV或3uA(两者取最大值) 即0.01×容量×电压的读数之内为合格品 | ||||||||||||||||||||||||||||||||||||||||||||

|

2 |

损耗角正切〥(120Hz) |

UR/V |

6.3V |

10V |

16V |

25V |

35V |

50V |

100V |

200V |

400V |

450V | ||||||||||||||||||||||||||||||||||

|

tgδ |

0.24 |

0.20 |

0.16 |

0.14 |

0.12 |

0.10 |

0.08 |

0.20 |

0.25 |

0.25 | ||||||||||||||||||||||||||||||||||||

|

3 |

耐久性(105°C) |

试验时间2000h (施加额定标称纹波电流电压) 1:漏电流, 不超过序号1规定值,(施加额定工作电压60秒读数) 2:电容量变化率, UR≤6.3V; ΔC/C≤+20%~30% 6.3V<UR≤100V;ΔC/C≤20% 3:损耗角正切, 不超过序号2规定值1.5倍或0.4取较大者. | ||||||||||||||||||||||||||||||||||||||||||||

|

4 |

低温特性 |

测试频率:120Hz

| ||||||||||||||||||||||||||||||||||||||||||||

|

5 |

高温储存特性 |

105℃环境中无负荷放置 1000小时后, 电容器的特性符合右表 的要求. | ||||||||||||||||||||||||||||||||||||||||||||

|

6 |

耐焊接热特性 |

经过回流焊并冷却至室温后, 电容器的特性符合右表的要求. | ||||||||||||||||||||||||||||||||||||||||||||

|

核准 |

李迪夫 |

审查 |

黄金霞 |

制表 |

杨玉灵 | |||||||||||||||||||||||||||||||||||||||||

CONTENTS 产品系列表

|

Type 类型 |

Series 系列 |

Features 特性 |

Capacitaner 电容量 |

Rated Voltage 额定工作电压 |

Operating 使用温度 |

Load Life 高温负荷 |

|

V-Chip 贴片型

|

CS |

Standard size 标准品 |

0.1~1500 |

4~100 |

-40~85 |

1,000 |

|

CK |

Standard size, wide temperature range 宽温标准品 |

0.1~1000 |

4~50 |

-40~+105 |

2,000 | |

|

CN |

Non-polarized 无极性品 |

0.1~100 |

6.3~50 |

-40~+105 |

2,000 | |

|

KP |

Non-polarized ,wide temperature range宽温无极性 |

0.1~47 |

6.3~50 |

-55~+105 |

2,000 | |

|

LZ |

Low impedance 低阻抗品 |

1~220 |

6.3~35 |

-55~+105 |

2,000 | |

|

KZ |

Extra lower impedance 极低阻抗品 |

1~1000 |

6.3~50 |

-40~+105 |

2,000 | |

|

EL |

Long life impedance 宽温长寿命品 |

0.1~1000 |

6.3~50 |

-55~+105 |

3,000 | |

|

WL |

5000 hours load life 5000小时长寿命品 |

0.1~1000 |

4~50 |

-40~+105 |

5,000 | |

|

HR |

High reliability 高可靠品 |

10~330 |

10~50 |

-40~+125 |

1,000 | |

|

General 85℃ 普通品 CD11型 |

RA |

For general purpose Standard size 标准品 |

0.1 ~22,000 |

6.3~100 |

-40~85 |

2,000 |

|

160~450 |

-25~85 |

2,000 | ||||

|

RN |

For general purpose Standard size 7mm标准品 |

0.1~470 |

6.3~63 |

-40~85 |

2,000 | |

|

RT |

For general purpose Standard size 5mm标准品 |

0.1~220 |

4~63 |

-40~85 |

2,000 | |

|

General 105℃ 普通品 CD110型 |

RK |

Standard size, wide temperature range 宽温标准品 |

1~33000 |

6.3`100 |

-40~+105 |

2,000 |

|

160~450 |

-40~+105 |

2,000 | ||||

|

RM |

Height 7mm,wide temperature range 7mm宽温标准品 |

0.1~470 |

4~63 |

-40~+105 |

2,000 | |

|

RS |

Height 5mm,wide temperature range 5mm宽温标准品 |

0.1~220 |

4~50 |

-40~+105 |

2,000 | |

|

Low Leakage 低漏电品 CD114 型 |

LA |

Standard size low leakage current低漏电品 |

1~3300 |

10!63 |

-40~85 |

2,000 |

|

LK |

Standard size low leakage current wide宽温低漏电品 |

0.1~330 |

10!50 |

-40~+105 |

2,000 | |

|

LM |

Height 7mm low leakage current 7mm低漏电品 |

0.1~100 |

6.3~63 |

-40~85 |

2,000 | |

|

LS |

Height 5mm low leakage current 5mm低漏电品 |

0.1~100 |

4~50 |

-40~85 |

2,000 | |

|

Non Polarized 无极性品

|

NP |

Non-polarized Standard size 无极性品 |

0.47~10000 |

6.3~250 |

-40~85 |

2,000 |

|

NK |

Non-polarized wide temperature range 宽温无极性品 |

0.1~10000 |

6.3~100 |

-40~+105 |

2,000 | |

|

NM |

Non-polarized height 7mm 7mm无极性品 |

0.1~47 |

6.3~50 |

-40~85 |

2,000 | |

|

NS |

Non-polarized height 5mm 5mm无极性品 |

0.1~47 |

6.3~50 |

-40~85 |

2,000 | |

|

NA |

For crossover network non-polarized交流电路无极品 |

1~100 |

25~200 |

-40~85 |

2,000 | |

|

NE |

For high output non-polarized 高输出无极性品 |

1~33 |

50 |

-40~85 |

2,000 | |

|

BP |

For horiz[ntal defection bi-polarized 双极性品 |

2.2~22 |

25~50 |

-40~85 |

1,000 | |

|

Lowesr&Loq 高频低阻抗品 CD288型 |

TM |

For switching power supplies 高频低阻抗品 |

470~6800 |

6.3~25 |

-55~+105 |

2,000 |

|

TN |

Extremely low impedancer eliabililt高可靠低阻抗品 |

1~15000 |

6.3~63 |

-55~105 |

5,000 | |

|

Sna-in Terminal 焊针品 扭角型 |

SM |

Snap-in terminal stadard series 焊针型标准品 |

33~47000 |

6.3~350 |

-40~+105 |

2,000 |

|

400~450 |

-25~105 | |||||

|

SK |

Snap-in terminal temperature range 耐高温焊针品 |

47~47000 |

10~400 |

-40~+105 |

2,000 | |

|

450 |

-25~105 | |||||

|

Special Type 特别型号 |

RF |

For photo fiash 闪光灯电路专用品 |

60~180 |

330 |

-20~+55 |

1,000 |

LEAD FREE TYPE REFLOW SOLDERING CONDITION

无 铅 焊 料 产 品 的 回 流 焊 条 件

l Recommended Conditions for Reflow Soldering 无铅焊料产品遵循的回流焊条件

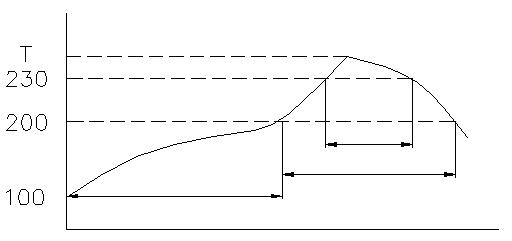

(1) Preheat shall be made at 100℃~200℃ and for maximum 180 seconds.

100℃~200℃的预热时间不得超过180秒钟。

(2) Period that temperature at top of capacitor becomes more than 200℃and 230℃shall not exceed t and t1 seconds, respectively.

电容器顶部温度高于200℃和230℃的时间,分别不得超过t和t1所限定的时间。

(3) Temperature at top of capacitor shall not exceed T(℃).

在回流焊接时,电容器顶部的最高温度不得超过T(℃)所限定的温度。

l Temperature/Time profile 回流焊温度与时间曲线图

| ||||||||||

| ||||||||||

| ||||||||||

| ||||||||||

| ||||||||||

l Allowable Range of Peak Temperature 不同壳号的焊接温度及时间

|

Size |

T(℃) |

t(second) |

t1(second) |

|

φ4~φ6.3 |

250 |

90 |

40 |

|

φ8×10.5L |

240 |

90 |

30 |

|

φ10×10.5L |

235 |

60 |

30 |

l Recommended Land Size 各种壳号的安装尺寸

(m m)

|

Size |

X |

Y |

a |

|

φ4 |

1.6 |

2.6 |

1.0 |

|

φ5 |

1.6 |

3.0 |

1.4 |

|

φ6.3 |

1.6 |

3.5 |

2.1 |

|

φ8×10.5L |

2.5 |

3.5 |

3.0 |

|

φ10×10.5L |

2.5 |

4.0 |

4.0 |

![]()

![]()

![]()

|

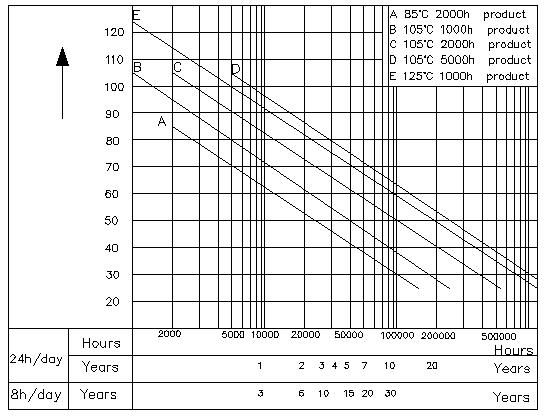

ALUMINUM ELECTROLYTIC CAPACITORS'LIFE

关于铝电解电容器的寿命

The life of non-solid aluminum electrolytic capacitors is mainly dependent on environmental conditions (e.g. ambient temperature, humidity etc.) and electrical factors(e.g. operating voltage, ripple current etc.).Generally, the wear-out mechanism of non-solid aluminum electrolytic capacitors is based on evaporation of electrolyte through the rubber seal. Consequently, the factor of temperature (ambient temperature and internal heating due to ripple current) is the most critical to electrolytic capacitor life. The effect of voltage on capacitor life is negligible, especially for low voltage electrolytic capacitors. The lifetime of non-solid aluminum electrolytic capacitors can be expressed as following equations:

非固体铝电解电容器的寿命主要依赖于使用环境条件(如环境温度,湿度等)和电负荷情况(如工作电压,纹波电流等)。通常而言,非固体铝电解电容器的失效机理被认为是电解液通过胶塞逐渐挥发导致的。因此,温度因素(环境温度及由于纹波电流而引起的内热)对电解电容器寿命有重大影响。相反,电压对电容器寿命的影响可以忽略,尤其对于低压电解电容器而言更是如此。非固体铝电解电容器的寿命可以用下列公式估算:

Le=Lo·Kt·Kr

Where 这里

Le expected life at operating temperature Te (h)

在工作温度Te℃下的预期寿命(h)

Lo specified life at maximum operating temperature To (h)

在最大工作温度To℃下的保证寿命(h)

Kt ambient temperature acceleration term

环境温度影响因子

Kr ripple current acceleration term

纹波电流影响因子

Kt= Lo·A(To-Te)/10

Where 这里

To maximum rated operating temperature(℃)

最大额定工作温度(℃)

Te actual ambient temperature(℃)

实际环境使用温度(℃)

A acceleration coefficient (For the range 35℃ to the maximum operating temperature, A≈2)

加速系数(对于从35℃到最高工作温度的范围, A≈2)

Kr=2(-△T/5)

Where 这里

△T an increase in core temperature by internal heating due to ripple current(℃)

由于纹波电流引起的内热造成电容器芯子的温升(℃)

(△T=core temperature-ambient temperature

芯子湿度-环境湿度)

△T can be estimated as follows △T可用以下公式估算:

△T= (i2·R)(β·S)

Where 这里

i ripple current (A rms)

通过电容器的纹波电流(A rms)

R equivalent series resistance of the capacitor(Ω)

电容器的等效串联电阻(Ω)

β heat radiation coefficient(W/℃·cm2)

铝壳的热辐射系数(W/℃·cm2)

S surface area of the capacitor (cm2)

电容器的表面积(cm2)

The expected life of the capacitor at lower temperature neglect of ripple current effect is shown in the following figure.

当忽略纹波电流影响时,电容器在较低温度下的预期寿命可参照下图.

Quick Reference Guide of the Expected Life 预期寿命快速参考图

![]()

Example: Where a 2000hrs/105℃ guaranteed product is used continuously at 60℃, it can be expected to have a life of 5 years.

例 如: 对于105℃ 2000小时的产品,如果在60℃环境中连续使用,它的预期寿命约5年。